Forums

- Forums

- Duggy's Reference Hangar

- USAAF / USN Library

- Boeing B-47 Stratojet

Boeing B-47 Stratojet

Post a reply

- Go to Previous topic

- Go to Next topic

- Go to Welcome

- Go to Introduce Yourself

- Go to General Discussion

- Go to Screenshots, Images and Videos

- Go to Off topic

- Go to Works in Progress

- Go to Skinning Tips / Tutorials

- Go to Skin Requests

- Go to IJAAF Library

- Go to Luftwaffe Library

- Go to RAF Library

- Go to USAAF / USN Library

- Go to Misc Library

- Go to The Ops Room

- Go to Made in Germany

- Go to Campaigns and Missions

- Go to Works in Progress

- Go to Juri's Air-Raid Shelter

- Go to Campaigns and Missions

- Go to Works in Progress

- Go to Skinpacks

- Go to External Projects Discussion

- Go to Books & Resources

-

3 years agoWed Mar 20 2024, 08:14pmDuggy

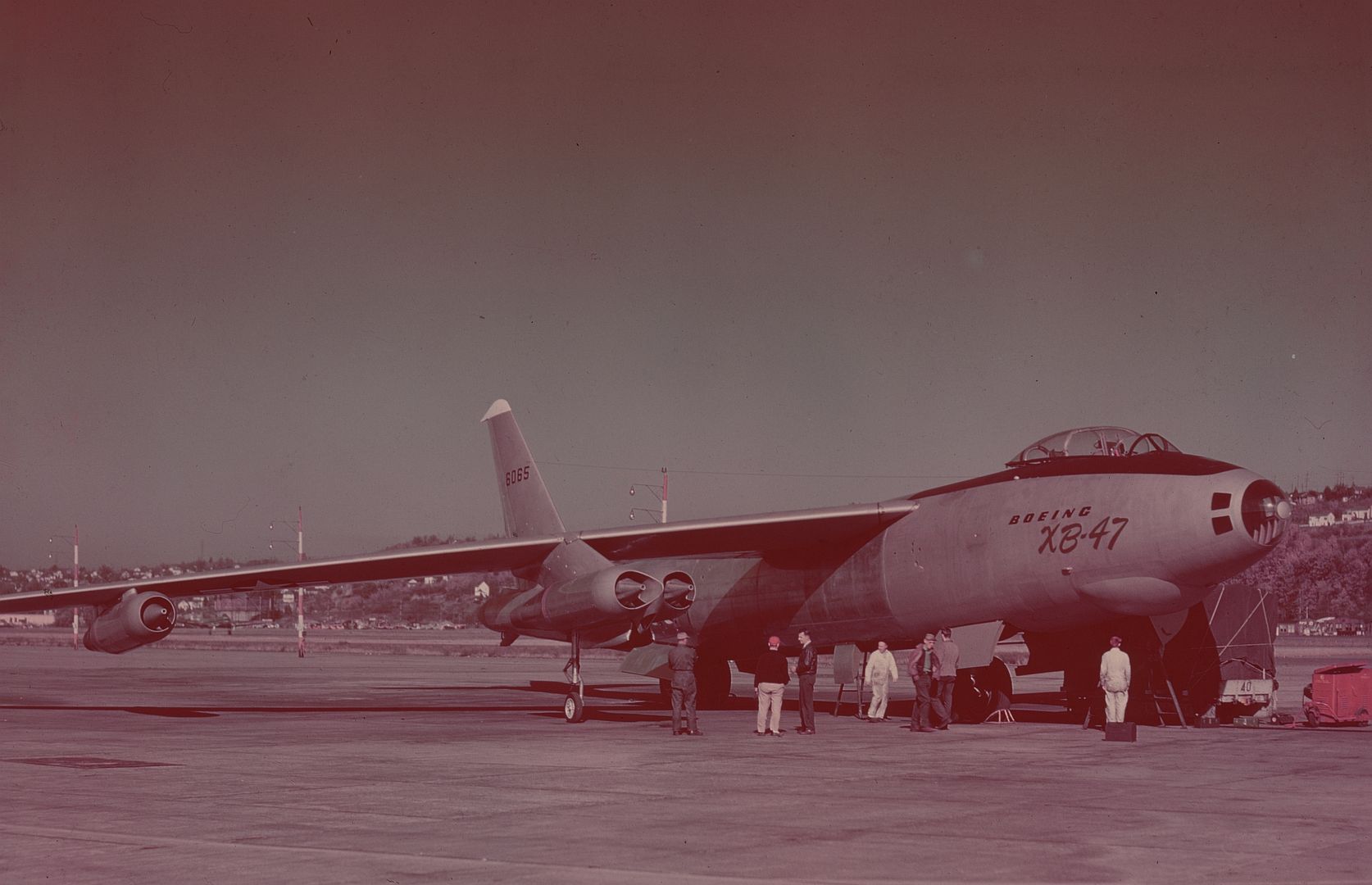

Main AdminBoeing XB-47 Stratojet

Main AdminBoeing XB-47 Stratojet

The Boeing B-47 Stratojet was the first swept-winged jet bomber built in quantity for any air force, and was the mainstay of the medium-bombing strength of the Strategic Air Command all throughout the 1950s. A total of 2042 Stratojets were built, making the B-47 program the largest American bomber project since the end of the Second World War.

The size of the crew (only three) was unusually small for an aircraft of the size and complexity of the B-47, with the three-member crew having to confront more than three hundred gauges, dials, switches, and levers. The B-47 went through a long gestation period during which many problems had to be fixed, and it took a long time before the Stratojet could be considered as being combat-ready. The early service of the B-47 was marked by frequent crashes and accidents, and the plane got a reputation as a crew-killer. Although there was nothing intrinsically wrong with the Stratojet, it was terribly unforgiving of crew mistakes or inattention. The B-47 was relatively difficult to land because of its high approach speed, unresponsive engines, and its unorthodox undercarriage. "Porpoising" on landing resulted in the loss of a number of aircraft. 55 percent of B-47 accidents were traced to human error, either by aircrews or maintenance personnel. It took a long time before more effective crew training was able to reduce the accident rate to a more acceptable level. By 1954, training had become sufficiently effective that the B-47 now had the lowest accident rate of any jet aircraft. Nevertheless, the B-47 never outlived its early reputation as a crew-killer. As veteran Stratojet pilot Brig. General Earl C. Peck observed in 1975, the B-47 was often admired, respected, cursed or even feared, but almost never loved.

The origin of the B-47 Stratojet can be traced back to the Second World War. In June of 1943, an informal USAAF request led several aircraft manufacturers to begin studies of multi-jet aircraft for fast photographic reconnaissance or medium bombing missions. On November 17, 1944, the USAAF issued formal requirements for a jet-powered medium bomber with a range of 3500 miles, a service ceiling of 45,000 feet, and a maximum speed of 550 mph.

Even before the USAAF began its study, Boeing had been working on the adaptation of large aircraft to jet propulsion. The initial Boeing study was known by the company as the Model 424, which was essentially a scaled-down B-29 with four jet engines paired in two nacelles mounted underneath the wing.

However, wind tunnel testing proved that this engine arrangement was unsatisfactory. In December of 1944, Boeing engineers went back to the drawing board and came up with the Model 432, in which all four engines were moved inside the main fuselage in order to improve the efficiency of the wing. The engines were located right over the main fuel tank area of the fuselage and were fed by bulbous air intakes located beside the cockpit section. The engines exhausted via tailpipes located on top of the rear fuselage. The aircraft still resembled the B-29 design, but with a much thinner wing.

The USAAF was sufficiently impressed with this design that they awarded Boeing a Phase I study contract for the Model 432 proposal. The project was assigned the designation XB-47. At the same time, contracts were awarded to North American for the XB-45, Convair for the XB-46, and Martin for the XB-48.

The configuration of the XB-47 was soon to undergo a drastic change. Just after V-E Day in May of 1945, the US Army's Scientific Advisory Group headed by the famous aerodynamicist Theodor von Karman was allowed to visit German aircraft factories and aeronautical research facilities to see if any of the innovations developed there could be incorporated into American designs. Boeing's chief aerodynamicist George Schairer accompanied the group. One of the items that was discovered was the results of some German research dating back to the mid-1930s on the use of swept-wings to improve the performance of high-speed aircraft. These studies confirmed independent studies carried out by NACA in the USA. The use of sweep angles as high as 45 degrees enhanced high-speed performance by delaying the formation of shock waves as the aircraft neared the speed of sound.

Word about the German research on swept wings was flashed back to Seattle, and Boeing engineers immediately stopped work on the straight-winged XB-47. Wind tunnel tests confirmed the essential validity of the German findings, and work began on a swept-winged version of the XB-47.

Early in September of 1945, Boeing was ready with the first swept-wing design for the XB-47, which was designated Model 448 by the company. It retained the fuselage of the Model 432 but featured a thin wing swept back at an angle of 35 degrees at quarter chord, and incorporated two more engines added in the extreme tail for a total of six. The other four engines were still mounted inside the upper fuselage, but were now fed by intakes cut into the extreme nose and exhausted over the top of the wing.

The USAAF felt that housing engines inside the fuselage constituted a fire hazard, and preferred designs which incorporated externally-mounted engines that would be easier to maintain or replace. In October of 1945, Boeing engineers returned to the drawing board and came up with the Model 450-1-1, which carried six jet engines mounted in pods--2 pairs in strut-mounted inboard nacelles suspended underneath the inner wing and single units in pods attached to the wingtips. The USAAF liked the change, and approved the Model 450-1-1 in October of 1945.

In November of 1945, the outboard engines were moved from the wingtips to pods underneath the outer wings 8 feet from the tip. The wingspan was increased to 116 feet. In December of 1945, the USAAF endorsed Boeing's proposal to build two flyable XB-47s. They would initially be built without any tactical equipment. In April of 1946, two XB-47 prototypes were ordered.

The XB-47 mockup was completed, inspected, and approved in April of 1946. Nevertheless, the Mockup Committee suggested some changes in the nose compartment, pilot and copilot seating, and landing gear arrangement.

Work on the actual prototype began in June of 1946. However, progress was hampered by problems with the design of the landing gear, control surfaces, as well as bottlenecks in the power plant installations. The thin swept wing made it impossible to suspend a landing gear from the wing or retract a wheel into it. The problem was solved by the installation of a tandem two-wheel landing gear which retracted into the fuselage. With both main two-wheel landing gear trucks on the fuselage centerline, a pair of small outrigger wheels which retracted into the inboard engine nacelles had to be added to achieve ground stability. This landing gear arrangement was previously tested on the Martin XB-26H "Middle River Stump Jumper", a B-26 Marauder that had been converted as a test aircraft.

Since neither main gear was sufficiently close to the aircraft's center of gravity to permit the traditional rotation method of takeoff from a level attitude, the aircraft was built so that it rested on the ground at the proper takeoff attitude.

Since the early turbojet engines had poor acceleration as compared to piston engines, it was felt that some additional thrust was needed for takeoff. This was provided by building in provisions for 18 solid-propellant JATO rockets inside the fuselage aft of the wing. Each JATO unit had a thrust of 1000 pounds.

The swept wing was fitted with a set of Fowler flaps on the inner trailing edges. When extended, the flaps moved aft a considerable distance from their nested position in the underside of the wing and then moved downwards.

The thin swept wing was extremely flexible, and the tips could flex 5 feet on either side of the normal position. Although the wing actually had no dihedral, it appeared to have a negative dihedral while on the ground because of the droop caused by its weight. Even in the air, the aircraft appeared to have negative dihedral because the tips of the wing, which was mounted as a positive angle to the centerline of the fuselage, were physically lower than the center section.

It was initially feared that the flexible wing would introduce controllability problems, because the deflection of conventional ailerons might tend to twist the wing in the opposite direction, nullifying or even reversing the aileron action. As a result, a set of spoilers were installed on the upper wing surfaces of the first prototypes to assist turn entry. However, it turned out that this precaution was unnecessary, and that the control was perfectly adequate with conventional ailerons, and the spoilers were deleted.

The crew was three, consisting of pilot, copilot/gunner, and bombardier/navigator. The pilot and copilot sat in tandem in separate cockpits underneath a fighter-type bubble canopy. The navigator/bombardier sat inside the nose behind a transparent nose cone. The bombardier/navigator in the nose had a radar bombing system inside an antenna that bulged below the nose in a plastic fairing.

The thin wing had no space for fuel tanks, so all fuel had to be carried inside the fuselage. This meant that serious attention had to be paid to fuel consumption management, since the mass of fuel was distributed along a considerable length of the aircraft.

It was assumed that the high speed of the XB-47 would protect it against attacks from all quarters except from the extreme rear, so only a tail defensive armament was provided. This consisted of a pair of 0.50-inch machine guns mounted in a turret in the extreme end of the tail cone. At first, an Emerson-built tail turret (referred to as the A-1 fire control system) with a cab for a tail gunner was to have been fitted. However, it proved to be too difficult to provide a cabin for a tail gunner, so a remotely-controlled system was chosen which would be operated by the copilot sitting in the rear seat underneath the cockpit canopy in the forward fuselage. He was able to swivel his seat around by 180 degrees to operate the tail armament via a separate panel. This eventually gave way to the A-2 fire control system, which eliminated the need for a separate tail gunner altogether. The A-2 system was designed to provide accurate defensive fire and had to be able to perform both search and track duties (although not simultaneously). The twin 0.50-inch tail guns could be controlled remotely from the cockpit or could be aimed and fired automatically by a radar-directed system that locked onto an aircraft attacking from the rear.

The first XB-47 (46-065) rolled out of the factory at Seattle on September 12, 1947. It was powered by six 2750 General Electric J35-GE-7/9 turbojets. It was the first large American jet aircraft to feature a swept wing.

The first flight of the XB-47 took place on December 17, 1947, with Bob Robbins and Scott Osler at the controls. On this first flight, the plane went from Seattle to nearby Moses Lake AFB in Washington state to begin a series of extensive flight tests.

The USAF tested the first XB-47 for about 83 hours, including 38 hours of Phase II flight tests which were carried out by Air Force pilots between July 8 and August 15, 1948. The Boeing pilots that first flew the XB-47 were enthusiastic. Test flights at Muroc that summer had demonstrated that the XB-47 was 74 mph faster than the Martin XB-48. However, its performance was below that expected. The ceiling was 2500 feet below that promised by Boeing, and 7500 feet lower than that originally required by the USAAF. Its speed was slower than expected.

The second XB-47 (46-066) was fitted with larger 5200 lb.s.t General Electric J47-GE-3 engines prior to its first flight. It flew for the first time on July 21, 1948. The new engines raised the top speed past the 600 mph level. The Air Force formally accepted the first XB-47 on November 29, 1948. The second XB-47 was accepted a month later.

The first XB-47 was later retrofitted with J47 engines, and flew with the J47s for the first time on October 7, 1949.

On September 3, 1948, the first production order was placed for the B-47. Since Boeing's Seattle facility was already heavily committed to the KC-97 tanker and the B-50 bomber, as well as to the conversion of obsolescent B-29 bombers to aerial tankers, it was decided that the production Stratojets were to be built at Boeing's factory in Wichita, Kansas, which had been leased from the government. Ten B-47As were ordered on October 28, 1948, and the first 88 B-47Bs were added to the contract on November 14, 1948. On November 22, 1948, the Air Force issued a Letter Contract which covered an initial order for 10 B-47As and the future procurement of three more B-47As and 41 B-47Bs. The three additional B-47As were later cancelled, and on February 28, 1949, the number of B-47Bs on order was raised from 41 to 55.

At the time of the production order, the weapon system concept had not yet been adopted by the USAF, but when it was, the B-47 became the first aircraft to receive a Weapon System designation, the bomber and photo-reconnaissance versions being WS-100A and WS-100L respectively.

On February 8, 1949, the first XB-47 flew from Moses Lake AFB, Washington to Andrews AFB near Washington, DC, averaging 602.2 mph over a 2289 mile course, setting an unofficial transcontinental speed record. While in Washington, the aircraft was shown to members of the House Armed Services Committee in the hope of obtaining sizeable production orders.

In 1954, after having been stripped of its wings and engines, the XB-47 was cut in half and exhibited at Palm Beach AFB in Florida.

Specification of XB-47

Engines: Six General Electric J35-GE-7 turbojets, rated at 3750 lb.s.t. each. Performance: Maximum speed 578 mph at 15,000 feet, 545 mph at 35,000 feet, 568 mph at sea level. Service ceiling 41,000 feet. Initial climb rate 3100 feet per minute. Range 2650 miles with 10,000 pound bombload. Ferry range 4000 miles. Dimensions: Wingspan 116 feet 0 inches, length 107 feet 6 inches, height 27 feet 8 inches, wing area 1428 square feet. Weights: 76,000 pounds empty, 125,000 pounds normal loaded, 162,500 pounds maximum takeoff. Armament: Two 0.50-inch machine guns in tail turret (not actually fitted). Normal bombload 10,000 pounds. Up to 16 1000-pound bombs or one 22,000 pound bomb could be carried.

Boeing B-47A Stratojet

On November 22, 1948, the Air Force issued a letter contract for an initial order of ten B-47A service test examples, and future procurement of three more B-47As was scheduled. The three additional B-47As were later cancelled. The ten B-47As were scheduled for delivery between April and November 1950.

Unlike the two prototypes, the B-47As (company designation Model 450-10-9) were all built at the government-owned but Boeing-operated factory in Wichita, Kansas. All subsequent Boeing-built Stratojets were also manufactured at Wichita. This was done because Boeing's Seattle plant was already committed to the KC-97 and B-50 projects, plus the revamping of obsolescent B-29s as mid-air refuelling tankers.

The first B-47A flew on June 25, 1950. The B-47A was essentially identical to the XB-47 prototypes, differeng externally only in having a framed Perspex nose cone in place of the fully-transparent nosecone of the prototypes. The B-47A was powered by six 5200 lb.s.t. J-47-GE-ll turbojets and retained the built-in JATO feature of the prototypes. It increased takeoff weight from 121,080 pounds to 151,324 pounds.

It took another year to deliver all ten B-47As on the order. Throughout 1950-51, flight testing of the B-47A and the first XB-47 continued. Unfortunately, neither plane was very safe to operate. Both the XB-47 and the B-47A were seriously underpowered, and critical braking problems occurred during aborted takeoffs and after gross weight landings on wet runways.

In order to reduce the length of the landing run, a 32-foot deceleration parachute was provided that was stowed underneath the tail just forward of the tail cone. Conventional solid parachutes could not stand the aerodynamic load imposed by such high speeds without ripping, so a special ribbon type of parachute originally developed in Germany was designed. This chute was deployed immediately after touchdown to help slow down the aircraft and shorten the landing roll. However, it soon became customary practice to deploy the drag chute while the B-47 was still a few feet in the air just before touchdown.

Since the poor acceleration characteristics of the jet engines of those times (it could take as long as 20 seconds to spool the engines up from idle) made go-arounds after an aborted landing hazardous, a second and smaller sixteen-foot drogue or deceleration parachute was developed that acted as an inflight air brake that made it possible to make landing approaches at relatively high engine powers. If a go-around became necessary, the drogue chute could be immediately jettisoned and the airplane could accelerate quickly. If the landing was normal, the drogue chute could be left attached while the main braking chute was deployed.

Following the end of the landing roll, both the landing and braking chutes were jettisoned at the end of the runway before the B-47 taxiied in. The chutes were recovered and repacked by the ground crews.

There were several problems with the ejection seat equipment of the B-47A. In fact, things got so bad that the ejector seats were actually removed after an XB-47 accident in which the pilot was killed. As a substitute, an additional escape hatch and bail-out spoiler were provided underneath the nose.

Deliveries of the B-47A to the USAF began in December of 1950. The B-47A entered service in May of 1951 with the 306th Bombardment Wing, Medium, based at MacDill AFB in Florida. The 306th was intended to act as a training outfit to prepare future B-47 crews. The B-47As were primarily training aircraft and were not considered as being combat ready, since most of them were unarmed and were initially without almost any of their vital electronic components. Only four of the ten had the K-2 bombing navigation system. The tail armament of two 0.50-inch machine guns was tested with an A-2 fire control system on 49-1906 and with an A-5 fire control system on 49-1908. None of the B-47As ever saw any operational duty, but some of them stayed with the Air Proving Command.

Specification of Boeing B-47A Stratojet

Engines: Six General Electric J47-GE-11 turbojets, rated at 5200 lb.s.t. each. Performance: Maximum speed 600 mph at 8800 feet. Service ceiling 38,000 feet. Combat ceiling 44,300 feet. Initial climb rate 3375 feet per minute. Combat radius 1550 miles. Range 2650 miles with 10,000 pound bombload. Ferry range 4000 miles. Takeoff ground run 6000 feet at sea level. Dimensions: Wingspan 116 feet 0 inches, length 106 feet 9 inches, height 27 feet 8 inches, wing area 1428 square feet. Weights: 73,240 pounds empty, 106,060 pounds normal loaded, 157,000 pounds maximum takeoff. Armament: Two 0.50-inch machine guns in tail turret (not actually fitted). Normal bombload 10,000 pounds. Up to 16 1000-pound bombs or one 22,000 pound bomb could be carried.

Boeing B-47B Stratojet

The B-47B (Model 450-11-10) was the first true production Stratojet. It was the first aircraft in the B-47 series that was truly combat-ready, the earlier B-47A being used strictly for training. 87 B-47Bs had been contracted for by the Air Force in November of 1949, but the outbreak of the Korean War in 1950 brought increased demands for Stratojets and the Stratojet program was destined to become the largest bomber production program since the end of the Second World War.

The first 87 B-47Bs contracted for in November of 1949 were due to be delivered between December 1950 and December 1951. The B-47B was to be built at the government-owned Boeing Plant II at Wichita, Kansas, since the Seattle plants were all committed to the manufacture of the B-50 and the C-97, as well as to the conversion of obsolescent B-29s to tankers.

The B-47B was general similar to the earlier Stratojets--it was just 3 inches taller than the B-47A and only 8 inches shorter. It was powered by six General Electric J47-GE-11 engines and had structural modifications that allowed takeoff weights as high as 200,000 pounds.

The B-47B had a Nesa glass windshield with special rain repellent that replaced the earlier windshield wipers. The glass was coated with a transparent chemical conductor of electricity, which enabled it to be kept free of ice. A single-point ground and air-to-air refuelling receptacle was fitted.

The B-47B was equipped with two external fuel tanks--one underneath each wing between the inboard and outboard engine nacelles. These tanks held an additional 1780 gallons of fuel each and could be dropped in flight.

The B-47B featured a twin 0.50-inch machine gun tail turret controlled by a radar sight and a fire control system, although very few B-47s were actually fitted with this armament because of chronic problems with the fire-control system.

A major external difference between the B-47B and earlier versions was in the extreme nose. The B-47B carried a K-2 bombing navigation system with a periscopic sight in a modified nose that replaced the transparent nosecone of the B-47A. The B-47B was also equipped with an AN/APS-54 warning radar and a set of AN/APT-5A electronics countermeasures devices.

In the interest of saving weight, the troublesome ejector seats that had initially been fitted to the B-47A were deleted on all B-47Bs. The B-47B was provided with a escape hatch system for emergency crew egress, with a spoiler door at the aircraft's main entrance to make in-flight escapes safer.

Following the outbreak of the Korean War, the USAF decided that it needed B-47s in greater quantity than the Boeing facilities could supply. Douglas and Lockheed were requested to join in the manufacture of B-47s in their own plants, reviving the "Boeing-Vega-Douglas" pool that had been established during World War II for the manufacture of the B-17 Fortress.

The Lockheed versions of the Stratojet were to be built at a government-owned plant in Marietta, Georgia (near Atlanta) which had been operated by Bell Aircraft during the war for the manufacture of the B-29-BA Superfortress. This plant had been shut down at the end of the war, but had been reopened in January 1951 for use by Lockheed to de-cocoon and prepare for operations 120 B-29s which had been in storage. The Lockheed-built Stratojets were designated B-47-LM.

The Douglas versions of the Stratojet were to be manufactured at a government-owned plant at Tulsa, Oklahoma which had been built during World War 2 and reactivated for operation by Douglas for the fulfillment of government contracts. The Douglas-built Stratojets were designated B-47-DT.

The Boeing-Wichita B-47s were designated B-47-BW to distinguish them from Seattle-built Boeings, which used the suffix -BO.

The Douglas company was awarded a production letter contract in December 1950, Lockheed soon afterwards. However, neither the Douglas nor the Lockheed plants started production before 1953. The first Stratojets built by these two additional plants were actually assembled from components supplied by Boeing-Wichita. Only ten B-47Bs were completed by Douglas-Tulsa and eight by Lockheed-Marietta (all of them built from Boeing-supplied components) before production switched over to the more advanced B-47E version. Douglas and Lockheed went on to build considerable numbers of B-47E Stratojets from scratch.

The first B-47B was accepted by the USAF in March 1951, and 87 similar planes were delivered within a year. However, these B-47s were almost immediately deemed unsuitable for the Strategic Air Command, and the Air Force recommended no less than 2000 changes. The plane was now seriously overweight, the maximum weight being over 200,000 pounds, which made the aircraft unstable at high altitude and generally hard to maneuver.

In spite of the deficiencies of the first B-47Bs, plans were made for the acquisition of more Stratojets. In November 1951, a definitive contract was issued for no less than 445 additional Stratojets. The number was reduced to 395 in March of 1952 after more realistic production schedules were established. Nevertheless, even more procurements soon followed. 52 RB-47s and 510 B-47Bs were ordered in June of 1952, and three other contracts were issued during the year--in September one for 540 B-47Bs, in October one for 70 RB-47s and in December one for another 193 B-47Bs. As it turned out, a total of 1760 B/RB-47s were ordered during 1952, but this order was later reduced and most of those that were built were actually delivered as B-47Es.

The omission of ejector seats from the B-47B turned out to be a serious mistake. SAC had always believed that ejector seats were the safest way to escape from a high-speed aircraft. Even under controlled flight conditions, escape from a B-47 via the escape hatch was hazardous, and it was for all practical purposes impossible to escape from an uncontrolled B-47 using such a system. In mid-1950, a request was made for the immediate reinstatement of the ejector seats, but it was clear that they could not be incorporated in production B-47s for quite a while, leaving as many as 400 B-47s still flying without ejector seats.

The K-2 bombing and navigation system initially fitted to the B-47B was unreliable and hard to maintain. It had 370 vacuum tubes and nearly 20,000 separate parts, with components scattered all throughout the aircraft. Inflight maintenance was impossible and failures were frequent. By mid-1952, the K-2 had been made to work better, but it still needed improvement even after additional modifications had resulted in its redesignation as the K-4.

The tail defense system originally earmarked for the B-47 was the Emerson A-2 which was to provide accurate defensive fire for the protection of the B-47 and to perform both search and track functions. However, the suitability of the A-2 for the B-47 was deemed too questionable to warrant its retention and it was cancelled at the end of 1951. The Emerson A-2 system was replaced by the General Electric A-5 system. Since the A-5 system would not be ready until the end of 1953, a stopgap measure was necessary, and it was decided to retrofit early B-47Bs with a two gun turret and an N-6 optical sight.

The 89th B-47B and all later B-47Bs were equipped with more-powerful J47-GE-23 engines rated at 5800 pounds of thrust. This resulted in a change of model number to 450-67-27. The first 88 B-47Bs were later retrofitted with these more powerful -23 engines.

Deliveries of the B-47B to the USAF began in mid-1951, the first unit to re-equip with the Stratojet being the 306th (Medium) Bomb Wing, comprising the 367th, 368th, and 369th Bomb Squadrons.

A refinement program began in January of 1952 to correct some of the B-47's problems. This involved the modification of 310 B-47Bs. The Strategic Air Command expected its first modified planes by July, and a monthly delivery of 75 by the end of the year, but this proved to be overly optimistic. At first, this work was to be done at the Grand Central Depot of Tucson, but it soon became apparent that the job was much too large for them and both Boeing and Douglas were asked to help. The original modification schedule began to slip, and in September of 1952, the few B-47Bs actually flying with SAC had to be grounded because of fuel cell leakages.

In spite of the delays, SAC began to receive its first modified B-47Bs in October of 1952. SAC received 8 modified B-47Bs in October 1952, 23 in November, 34 in December in 13 in January 1953. They went to the 306th and 305th Wings. In June of 1953, B-47Bs from the 306th Wing began a 90-day rotational training mission to England, marking the first overseas deployment of the B-47B.

The last B-47B was built in June of 1953, with the USAF taking delivery the next month. A total of 399 B-47Bs were built, all of them manufactured by Boeing-Wichita, although final assembly of a few B-47Bs was carried out at Lockheed and Douglas from components supplied by Boeing. Production was immediately shifted to the B-47E version, which was destined to become the major production version of the Stratojet.

Under a retrofit program known as High Noon begun in May of 1953, SAC's B-47Bs underwent an extensive modification and maintenance program to bring them up to the latest standards, which was essentially that of the B-47E. As approved in June of 1953, 165 of SAC's modified B-47Bs would go through High Noon, and the remainder would be upgraded during Ebb Tide, which was organized as High Noon's second phase. The modifications featured the installation of ejector seats for all crew members, a more reliable bombing/navigation system, the deletion of the fixed JATO units in favor of a jettisonable 19- or 33- rocket assisted takeoff pack, a modified bomb bay that could carry the thermonuclear bomb, a reinforced landing gear which could handle higher takeoff weights, the A-5 fire control system (in place of the B-4), an AN/ARC-21 long-range radio, and better electronics countermeasures equipment. 6000 lb.s.t. J47-GE-25 engines with water injection were installed, and General Electric radar-directed 20-mm cannon were installed in the tail in place of the 0.50-inch machine guns.

The High Noon program was finished in early 1956, and was immediately replaced by Ebb Tide. By 1957, the B-47Bs had effectively ceased to exist, having either been brought up to the B-47E standard or else having been sufficiently transformed as to acquire new designations. These modified B-47Bs are sometimes known as B-47B-II, although this was not an official Air Force designation. Outwardly, they could be distinguished from B-47Es only by their serial numbers.

The B-47B was used for a variety of test projects and special role conversions. Twenty-four B-47B aircraft were converted to the daytime photo-reconnaissance role with the addition of a camera pallet in the forward bomb bay. These aircraft were redesignated RB-24B. The YRB-47B was a trainer version designed for crew transition training into the RB-47E. Drone director conversions were designated DB-47B, and a single aircraft converted for testing the Bell GAM-63 Rascal air-to-surface missile was designated YDB-47B. A single B model was converted to the weather reconnaissance role and designated WB-47B. The aircraft was assigned to the 55th Weather Reconnaissance Squadron. Finally, a number of B-47Bs were modified as crew trainers and designated TB-47B. The major change to this type was the addition of a fourth crew position for the instructor pilot.

Specification of Boeing B-47B Stratojet

Engines: Six General Electric J47-GE-23 turbojets, 5970 lb.s.t. each Performance: Maximum speed 608 mph at 16,300 feet, 565 mph at 35,000 feet. Cruising speed 498 mph. Stalling speed 177 mph. Service ceiling 33,900 feet, combat ceiling 40,800 feet. Initial climb rate 2560 feet per minute. Combat climb rate 4775 feet per minute (maximum power). Combat radius 1965 miles with 10,00 pounds of bombs. 4444 miles ferry range. Takeoff ground run 9100 feet, 7200 feet with JATO. Dimensions: Wingspan 116 feet 0 inches, length 106 feet 10 inches, height 27 feet 11 inches. wing area 1428 square feet. Weights: 78,102 pounds empty, 122,650 pounds combat, 184,908 pounds gross. Armament: Two 0.50-inch machine guns in tail. Up to 18,000 pounds of bombs could be carried.

Boeing RB-47B Stratojet

RB-47B was the designation initially given to a proposed photo-reconnaissance version of the B-47B Stratojet. It was designed to replace the RB-29 and RB-50 aircraft which were serving in the long-range photo-reconnaissance role but which were rapidly approaching obsolescence.

The design of the RB-47B began in March of 1951. Shortly before October 1952, it was decided that the plane would feature the A-5 fire control system as well as the still-experimental J47-GE-25 engines. Since it was projected that the RB-47B would not be ready before 1954, and by the time that the RB-47B was completed it would more closely resemble the B-47E than the B-47B, the reconnaissance version of the Stratojet was redesignated RB-47E.

What actually became known as the RB-47B were 24 B-47Bs that were converted to reconnaissance configuration in 1953-54 by adding a special 8-camera heated pod in the forward bomb bay. Unlike the later RB-47E, the RB-47B could only provide daylight photographic coverage.

The YRB-47B was a later conversion of the B-47B specifically intended for the training of crews for RB-47Es. The 91st Strategic Reconnaissance Wing (Medium) received its first YRB-47B in April of 1953, the 26th 3 months later.

In 1953 a decision was made to also equip 320th BW at March AFB with YRB-47Bs. The conversions were carried out by Douglas and by the Grand Central aircraft companies. Between July and November, 1953, the 320th received 44 YRB-47Bs. In November of '53, the Wing began to restore all of these planes back to bomber configurations, completing all re-conversions by March, 1954. Eventually, these were exchanged through "High Noon" and other programs.

Brass Ring

From the start, the B-47 bomber had been designed with the capability of delivering nuclear weapons. The hydrogen bomb program, whose development began during the late 1940s and was pressed to completion during the early 1950s, promised to increase the destructive power of nuclear weapons by almost a hundredfold. However, the thermonuclear bomb did present a special problem not encountered by the less-powerful atomic bomb--it was expected to deliver such a lethal blast that it would destroy any aircraft releasing it in the conventional manner.

In 1949, the Air Force began work on a super-secret program to develop an effective delivery system for the upcoming hydrogen bomb. At first, it was thought that only missiles would be suitable for the delivery of the hydrogen bomb. However, in 1949 was estimated that it would take at least three years before any of the missiles that were then under development could be ready. In search of a delivery option that would be available sooner, the Air Force settled on the use of an unmanned aircraft. At the time, only three aircraft could meet the basic load and range requirements--the B-36, B-47, and B-49. Of these, the B-47 seemed to be the most suitable.

Early in 1950, it was decided that one of the ten B-47As expected to be delivered by 1951 would be converted into a drone director aircraft under the designation DB-47A. In support of the program, two future B-47Bs would be modified to unmanned hydrogen bomb carrier (MB-47) configuration. The Air Force was still uncertain about the details of how the MB-47 would operate--one possibility was that it might dive onto its target like a conventional missile, with another option being to release its bomb in the normal fashion and then be destroyed by the blast.

In April of 1951, the program was given the code name Brass Ring. Unfortunately, very little information was available about the size and weight of the future H-bomb, but it was expected to be large and heavy. Consequently, it was assumed that the B-47 drone would have to be refuelled in midair several times in order to reach its target. This meant that the drone would have to carry a crew until the very last refuelling operation. The crew would then bail out over friendly territory and the deserted MB-47 would proceed on to its target guided by autonomous stellar tracking systems or by auto-navigation. The design of a fully-automatic, non-jammable guidance and bombing system provided a major challenge, so the Air Force started to consider the possibility of using a director DB-47 that would accompany the MB-47 drone all the way to the target.

Boeing subcontracted North American Aviation to develop the autonavigation equipment. The Sperry Gyroscope Company was to supply the automatic flight control equipment, and the Collins Radio Company would supply the guidance equipment.

None of these schemes ever reached fruition, because it was found that it was perfectly feasible to deliver hydrogen bombs the old-fashioned way. It was found that a B-36 could release a parachute-equipped H-bomb over a target with an adequate margin of safety for escape. The Brass Ring program was officially canceled on April 1, 1953.

The B-47 Rascal Program

The YDB-47B version of the Stratojet was intended to carry the Bell GAM-63 Rascal air-to-surface guided missile. The designation Weapons System 112L was also assigned to the Rascal project, and the project development began in 1949.

The name "Rascal" was actually an acronym which stood for RAdar SCAnning Link, so named for the guidance system that was to be used during the missile's final dive onto the target. This guidance system was to be installed aboard the controlling aircraft. This system was to be developed jointly by Bell Avionics, Radio Corporation of America (RCA), and Texas Instruments.

The GAM-63 missile was powered by a Bell-designed liquid-fuelled rocket engine made up of three vertical in-line thrust chambers and developing a thrust of 4000 pounds. It had a launch weight of about 13,000 pounds and was 31 feet long with a body diameter of 4 feet. At a top speed of Mach 2.95, the missile could carry a 3000-pound nuclear warhead up to 100 miles.

The Strategic Air Command was never very enthusiastic about the Rascal program, believing that the missile was far too complex, with a guidance system that was likely to be prone to frequent failures and which would be relatively easy for an enemy to jam. However, the Air Staff pushed hard for the Rascal concept, and SAC was forced to go along.

The Rascal missile as originally conceived was earmarked for the Convair B-36 and B-60, as well as for the B-47 and B-52. In March of 1952, the list of candidate aircraft for the Rascal was reduced to just the B-36 and B-47, with the B-47 being assigned the first priority.

The first Rascal air launch took place on September 30, 1952 from a modified Boeing DB-50D. Despite official resistance from SAC, in 1953, B-47B serial number 51-2186 was modified as a Rascal carrier under the designation YDB-47B. The missile was to be suspended from the starboard side of the fuselage. At launch, the missile would be released from its supports, with the rocket motor firing once the Rascal had dropped a safe distance away from the YDB-47B. In addition, two B-47Es (51-5219, 51-5220) were earmarked for conversion to Rascal carriers.

As the Rascal program proceeded, SAC's sense of unease increased still further. SAC felt that equipping the B-47 fleet with the large and bulky externally-mounted Rascal would degrade the aircraft's performance to such extent as to make the whole concept of dubious value. SAC also feared that the guidance system would never work very well, and they were reluctant to add even more complex electronic equipment to an already electronically-packed B-47. Modification costs (about a million dollars per aircraft) were high, and personnel training demands were considerable. Nevertheless, the Air Force decided in June of 1955 that the B-47 and not the B-36 would carry the GAM-63, and most of the DB-36 modification contract was cancelled. As part of the program, 30 B-47Bs, originally earmarked for Ebb Tide would now be converted to DB-47 configuration as Rascal carriers.

Despite a successful first Rascal launch from a DB-47E in July of 1955, the entire project soon began to falter. In early 1956, it was decided that the requirements for DB-47Es would be limited to only the first two. In May of 1957, it was announced that only one rather than two DB-47/GAM-63 squadrons would be fielded. That still did not satisfy SAC, since they felt that the entire Rascal idea would be outmoded by the time it achieved operational status. Nevertheless, by the end of 1957, crews of the 321st Bomb Wing were heavily involved in Rascal training.

It was planned that the 321st Wing's 445th Bombing Squadron would operate with the Rascal from Pinecastle AFB in Florida. Formal acceptance of the first production GAM-63 took place at Pinecastle AFB on October 30, 1957. However, the program soon encountered snags and delays, and even by early 1958, Rascal facilities were still not yet in place at Pinecastle.

My sources differ on the effectiveness of the Rascal. Pelletier claims that the Rascal turned out to be a fairly accurate and effective missile, with examples from the service test batch scoring four consecutive direct hits on targets at the Air Force Missile Development Center in New Mexico. In point of contrast, Knaack concluded that the results of Rascal testing were dismal, with only one out of 64 scheduled launches being a complete success, more than half having to be cancelled, and the others being complete failures.

In any case, the Rascal concept rapidly became obsolete in the face of new developments in the field of air-launched missiles. SAC finally got its way, and the Rascal program was formally cancelled on September 9, 1958. On November 18, AMC was directed to dispose of the 78 experimental and 58 production Rascal missiles that had been accepted.

Boeing TB-47B Stratojet

The TB-47B was a conversion of the standard B-47B as a transition trainer for pilots and navigators. It was basically similar to the B-47B but had a fourth crew position added for an instructor. All armament and ECM equipment was removed. 48 B-47Bs were modified to TB-47B configuration at Douglas-Tulsa, and 18 were modified by the USAF at Oklahoma City

Boeing WB-47B Stratojet

In 1956, a single B-47B (51-2115) was modified by General Precision Laboratories as a weather reconnaissance aircraft under the designation WB-47B. This project was carried out at the request of the US Congress in response to the disastrous 1954 hurricane season (which I remember). The WB-47B was used to penetrate hurricanes and to perform other weather-related duties. In November 1958, the WB-47B aircraft began to do research work in collaboration with the Tiros II weather satellite, the first of the weather satellites.

The WB-47B logged 126.5 hours of flight time before it was retired in 1963 when more efficient WB-47Es became available.

Boeing YB-56/B-47C Stratojet

The early versions of the Stratojet were all severely underpowered, and in pursuit of a more powerful Stratojet the Air Force proposed a version of the B-47 powered by four 10,090 lb.s.t. Allison J71-A-5 turbojets. The designation YB-56 was assigned to this project, since the different engine configuration was thought to justify a change in designation. A reconnaissance version known as RB-56A was also planned. According to the original planning, the 88th B-47B (50-092) was scheduled be converted to YB-56 configuration as a testbed for the concept.

For a time, the YB-56 was intended to be the "definitive" Stratojet. However, since the airframe was basically that of a "stock" B-47B, the designation of the YB-56 was changed to YB-47C. The J71 engine was later found to be unsuitable for the Stratojet, and a decision was made to switch to the new Pratt & Whitney YJ57 turbojet. However, these engines were not yet available, and in any case they were already earmarked for the B-52. Consequently, the YB-47C program was cancelled in December of 1952, and no four-jet Stratojet was ever built.

Boeing XB-47D Stratojet

During the late 1940s and early 1950s, turboprop engines were still considered as a viable option for long range bombers, and the USAF was interested in determining the feasibility of producing a high speed, long-range turboprop-powered bomber. In support of this goal, the Air Force requested that a pair of B-47Bs be converted as flying testbeds to test a jet engine-propeller combination and to provide data on the installation of turboprops in swept-wing aircraft.

In April 1951, Boeing received a contract for the modification of two B-47Bs as flying turboprop testbeds under the designation XB-47D. The two B-47Bs selected for the conversion were serial numbers 51-2103 and 51-2046. They were assigned company numbers of Model 450-162-48 and 450-162-49 respectively. They retained the outboard J47-GE-23 jet engines of the B-47B, but a single Curtiss-Wright YT49-W-1 turboprop of 9710 equivalent shaft horsepower occupied each of the inboard underwing nacelles in place of the paired J-47s. The T49 was a turboprop version of the Wright J65, which was in turn an American version of the British-designed Armstrong Siddeley Sapphire turbojet. The turboprops drove four-bladed propellers 15 feet in diameter having paddle type blades each 24 inches wide. The wing flaps had to be modified to accommodate the T49s, and changes had to be made in instrumentation and controls for four engines rather than the usual six.

The program was delayed by problems with the T49 engine, which failed to pass its 50-hour qualification run. Additional problems with the engine-propeller combination and shortages of government-furnished equipment delayed progress still further. It was not until late 1955 that the aircraft were ready for their first flights.

XB-47D 51-2103 flew for the first time on August 26, 1955, with 51-2046 following on February 15, 1956. Surprisingly, the performance of the XB-47D was fairly similar to that of the conventionally-powered B-47, and landing performance was improved with the addition of the fully-reversible propellers of the XB-47D.

Although numerous test flights were made without mishap, no further conversions were ordered and the Air Force did not pursued its idea of a turboprop-powered bomber any further. The maximum speed achieved by the XB-47D during these tests was 597 mph at 13,500 feet, the fastest yet achieved in level flight by a propeller-driven aircraft.

Specification of Boeing XB-47D

Two Wright YT49-W-1 turboprops, 9710 shaft hp each, plus two General Electric J47-GE-23 turbojets, 5800 lb.s.t. each. Performance: Maximum speed 597 mph at 13,500 feet. Service ceiling 33,750 feet. Initial climb rate 2910 feet per minute. Dimensions: Wingspan 116 feet 0 inches, Length 108 feet 0 inches, height 28 feet 0 inches, wing area 1428 square feet. Weights: 79,800 pounds empty, 184,428 pounds gross takeoff. Armament: The XB-47D was not fitted with any armament. -

3 years agoSat May 13 2023, 09:37amDuggy

Main AdminBoeing B-47E Stratojet

Main AdminBoeing B-47E Stratojet

The B-47E (Model 450-157-35) was the major production version of the Stratojet. It was the only version that was mass-produced by all three members of the Stratojet production pool--a total of 1341 B-47Es were built--386 by Lockheed, 264 by Douglas, and 691 by Boeing.

The B-47E was basically the standardized production version of the Stratojet, and incorporated many innovations that had been suggested by experience with the B-47B. It standardized on six General Electric J47-GE-25 engines, which offered a thrust of 7200 pounds with water injection. These engines had already been refitted to several B-47Bs. The 18-unit internal JATO system was retained on early models, but was soon replaced by a jettisonable rack that contained 33 1000 lb.s.t units that could be dropped following takeoff. The B-47E was fitted from the start with an approach chute to increase drag and a brake chute to decrease the landing roll. An anti-skid braking device was also fitted.

The defensive armament was changed to two 20-mm cannon in the tail. The A-5 fire control system that had taken so long to develop was finally fitted. The A-5 fire control system was much better than the discarded B-4 system of earlier versions, and could automatically detect and track pursuing aircraft and aim and fire the 20-mm cannon. The earlier B-4 system could at best spray machine gun fire in the general direction of an attacking plane, without much prospect of actually scoring a hit.

The B-47E incorporated as standard equipment an inflight refuelling receptacle for flying-boom midair refuelling on the starboard side of the nose. The use of inflight-refuelling capability enabled the total fuel capacity to be reduced to 14,610 gallons, including two 1700-gallon drop tanks carried underneath the wings between the engine nacelles.

The crew was finally provided with ejector seats as standard equipment, with the pilot and copilot ejecting upward over the tail and the bombardier/navigator ejecting downward through a hatch in the lower nose.

The undersurfaces and lower portion of the fuselage of most B-47Es were painted a glossy white to reflect the heat radiation from nuclear blasts. This reflective paint was applied retroactively to some B-47Bs.

During FY 1953 production, a clamshell cockpit canopy was introduced, hinged on the right side.

The first B-47E flew on January 30, 1953, and the Air Force accepted this plane in February. By mid-year, 127 similar production examples had been delivered. The first B-47Es went in April 1953 to the 303rd Medium Bomb Wing based at Davis Monthan AFB in Arizona. The next recipient of the B-47E was the 22nd Wing at March AFB in California, retiring their B-47Bs to the Air Training Command.

By mid 1953, peak B-47 procurement was expected to reach almost 2200, but was cut by 140 in September 1953. A further production cut of 200 aircraft considered in October was prevented in favor of a 20-month production stretchout during the period in which the B-52 production line was getting up to speed. In contrast to the B-36 program, which was on the verge of cancellation several times, there was never any significant effort to cancel the B-47 program.

The B-47E rapidly became the dominant component of the USAF strategic deterrent during the mid- and late-1950s. By December of 1953, SAC had 8 B-47 Medium Bomber Wings. In December 1954, the SAC inventory counted 17 fully-equipped B-47 wings. By the beginning of 1956, 22 medium bombing wings had received the B-47, and another 5 wings were getting ready to convert to the B-47. In December 1956, SAC had 27 combat-ready B-47 wings, with 1204 combat-ready B-47 crews and 1306 B-47 aircraft assigned.

Progressive modifications resulted in four sub-variants of the B-47E.

The first of these, designated B-47E-I, introduced water/alcohol-injected J-47-GE-25A engines, rated at 7200 lb/st each. Phase II ECM equipment was provided, denoted by a small circular antenna on the rear fuselage. Maximum takeoff weight was 200,000 pounds.

A modified landing gear allowing heavier takeoff weights appeared on the 521st and subsequent B-47Es, and this configuration was labeled B-47E-II. Other modifications included the addition of Phase III ECM gear, which consisted of an AN-ALT-6 jammer mounted in a bulged fairing underneath the rear fuselage and antennae housed in wingtip extensions. The first B-47E-II reached the Air Force in August of 1953.

The B-47E-III introduced a three-phase electrical power supply

A far stronger landing gear was incorporated on the 862nd and later B-47E. This configuration was known as B-47E-IV. The IV also introduced a series of electronics upgrades including the MA-7A bombing radar, the AN/ASP-54 warning radar, and the AN/APG-39 gun-laying radar. The B-47E-IV had a takeoff weight of 230,000 pounds, 28,000 pounds more than previously permissible. This extra weight was largely devoted to extra fuel, enabling the combat radius of the IV to increase to 2050 nautical miles, almost twice the distance demonstrated 5 years earlier by the first B-47A. The maximum warload was 25,000 pounds.

The Air Force received its first B-47E-IV in February 1955. In March of 1955, it was decided that all active B-47s would be brought up to the IV standard.

Spurred by the Suez crisis of 1956, SAC demonstrated its ability to launch a large striking force on short notice when in December more than 1000 B-47s flew nonstop, simulated combat missions, averaging 8000 miles each over the American continent and Arctic regions.

Early in 1955, the Strategic Air Command requested the B-47 be adapted for low-level bombing, with the aircraft delivering its bomb via the toss-bomb technique. In a toss-bombing attack, the plane enters the run at low altitude, pulls up sharply into a half loop with a half roll on top and releases the bomb at a predetermined point in the climb. The bomb continues upward in a high arc, falling on the target at a considerable distance from its release point. In the meantime, the maneuver allows the airplane to reverse its direction and gives it more time to speed away to a safe distance from the blast. This technique was adopted because it was thought that high-speed B-47s flying at low level would be less vulnerable to enemy countermeasures. The existence of low-level capable B-47s would mean that a potential enemy would now be faced with threats from both high- and low-level attacks.

In June of 1955, a 6000-pound dummy bomb was successfully released from a B-47E during a 2.6g pullup from level flight. In another test flight, an 8850-pound practice bomb was dropped from a 2.5-g pullup. Despite some doubts about the structural integrity of the B-47 under the stresses involved in such maneuvers, in December 1955 SAC ordered that 125 B-47s be modified for low-level flight.

Low-level bombing involved special crew training. A training program known as Hairclipper was started in December of 1955. However, adverse weather, excessive maintenance requirements, serious deficiencies in LABS systems, and several accidents caused Hairclipper to be officially discontinued in March of 1958. However, the end of Hairclipper did not signify the end of low-level flying. A program known as Pop Up, a related training program that took advantage of recent advances in weapons developments, fared better. In the Pop Up maneuver, the aircraft came it low level, pulled up to high altitude, released its weapon, and then dove steeply to escape being spotted by enemy radars. Following the discovery of fatigue cracks in the wings of some B-47s in April of 1958, Pop Up was interrupted while the entire B-47 fleet could be checked. It was resumed in September, and by the end of 1959 the training program had finally been completed.

On January 25, 1957, a B-47 flew from March AFB, California to Hanscom Field, Massachusetts in 3 hours, 47 minutes, at an average speed of 710 mph (assisted by strong tailwinds). On August 14, 1957, a 321st Bomb Wing B-47 made a record nonstop flight from Andersen AFB, Guam to Sidi Slimane Air Base in French Morocco, a distance of 11,450 miles in 22 hours and 50 minutes. This required 4 midair refuellings. In November of 1959, a B-47 assigned to the Wright Air Development Center stayed in the air for 3 days 8 hours 36 minutes, covering 39,000 miles. This broke previous time-and-distance records.

The discovery of fatigue cracks in the wings of the B-47 during April of 1958 and a rash of new accidents in early 1958 triggered an immense inspection and repair program known as Milk Bottle. All three B-47 manufacturers as well as the AMC were involved in Milk Bottle. The low-level B-47s of the 306th and 22nd Bomb Wings were the first to enter the program, since they were most in danger of fatigue cracking. The program ended in July of 1959. Although Milk Bottle did not solve all the B-47's problems, it did go a long way in making operations with the B-47 a lot safer.

SAC initially wanted 1000 B-47s modified for low-level flying, which meant fitting virtually the entire Stratojet fleet with absolute altimeters, terrain-avoidance equipment, and Doppler radar. Because of the Milk Bottle repair program, testing delays, and the phaseout of some SAC B-47 wings due to a lack of funds, SAC was forced to scale down its low-altitude requirements to only 500 Stratojets. This program was given a new sense of urgency by the belief that by 1963 all B-47s would be hopelessly obsolete if they were not equipped for low-level flight. However, fund shortages dictated that SAC scale down its low-altitude requirements to only 350 aircraft.

A total of 691 B-47Es were built by Boeing-Wichita, Douglas-Tulsa built 264, and Lockheed-Marietta built 386. The final B-47E (53-6244) was delivered in 1957 to the 40th Bomb Wing, 44th Bomb Squadron at Schilling AFB in Salina, Kanses. 53-6244 was transfered to Lincoln AFB, Nebraska where it remained until it was transfered to the USAF Museum at Wright Patterson AFB, Ohio. Reports that 53-6244 served at Pease AFB are incorrect.

The beginning of the phaseout of the B-47E coincided with the delivery of the last example. In 1957, the 93rd Bomb Wing started exchanging its B-47s for B-52s. In March of 1961, President John F. Kennedy directed that the phaseout of the B-47 be accelerated. However this was delayed in July by the onset of the Berlin crisis of 1961-62. In the following years, B-47s were gradually delivered to the storage facility at Davis-Monthan AFB. SAC's last two B-47s went to storage on February 11, 1966.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

Specification of Boeing B-47E Stratojet

Engines: Six General Electric J47-GE-25 turbojets, 5970 lb.s.t dry and 7200 lb.s.t. with water injection. Performance: Maximum speed 607 mph at 16,300 feet, 557 mph at 38,500 feet. Cruising speed 500 mph. Stalling speed 175 mph. Service ceiling 33,100 feet, combat ceiling 40,500 feet. Combat climb rate 4660 feet per minute (maximum power). Combat radius 2013 miles with 10,845 pound bombload . 4035 miles ferry range withy 16,318 gallon fuel load. Takeoff ground run 10,400 feet, 7350 feet with JATO. Dimensions: Wingspan 116 feet 0 inches, length 107 feet 0 inches, height 27 feet 11 inches, wing area 1428 square feet. Weights: 79,074 pounds empty, 133,030 pounds combat, 198,180 pounds gross, 230,000 pounds maximum takeoff. Armament: Two 20-mm M24A1 cannon in extreme tail. Maximum bombload 25,000 pounds.

Boeing EB-47E Stratojet

Two modified B-47Es (52-410 and 52-412), redesignated EB-47E, were loaned to the US Navy for electronic warfare tests. The long-range external wing tanks were replaced with a variety of pods filled with electronic countermeasures equipment, and more chaff dispensers were installed. They were assigned the BuNos of 24100 and 24102 respectively, which conflicted with a batch of WW2 Grumman TBF Avengers. These two planes remained operational with the Navy long after after the last USAF B-47s had been retired. They were finally retired in December of 1977.

Some references list a third Navy EB-47E, 53-2104.

The designation EB-47E was also applied to a number of USAF electronics countermeasure conversions of the standard B-47E. The first of these was equipped with what was known as the Phase IV (or Blue Cradle) ECM package, consisting of 16 AN/ALT-6B electronic jammers mounted on a cradle inside the bomb bay. Phase V aircraft carried a pressurized capsule inside the bomb bay that carried two electronics warfare officers that operated a suite of up to 13 different jammers that could focus on specific threats. Not much is known about the USAF EB-47E program, but it is believed that up to 40 B-47Es were converted to either Phase IV or V standard.

EB-47E(TT) Telemetry Intelligence Gatherer

At the beginning of the space race between the USA and the USSR, the USAF wanted a way of monitoring the telemetry that was broadcast during Soviet space launches from the IRBM facility at Kasputin Yar and the space center at Tyuratam. One solution was to have an aircraft packed with electronic sensors to fly at a high altitude near these facilities during these Soviet launches, intercepting and recording the electronic telemetry for later analysis by US experts.

Three standard B-47Es were modified to meet this requirement. Designated EB-47E(TT), where the TT stood for Tell-Two, they were fitted with a crew capsule in the bomb bay that carried a pair of electronic warfare officers. An external fairing carring sensor antennae was fitted to each side of the nose.

At any one time, two of the EB-47E(TT) aircraft would stand alert at Incirlik AB in Turkey, ready to scramble at a moment's notice as soon as an impending Soviet launch was detected. For launches out of Kasputin Yar, missions were flown over the Black Sea, and for launches out of Tyuratam the missions were flown over northeastern Iran. During the missile flights, the missions were flown at as high an altitude as possible in order to obtain the clearest reception of the telemetry.

The EB-47E(TT) aircraft served from 1958 until about 1967. Serials were 53-2315, 53-2316 and 53-2320.

Boeing ETB-47E Stratojet

After 1959, some B-47Es were used for training under the designation ETB-47E. As in the case of the TB-47B, the converted ETB-47E had a fourth crew seat for the instructor.

Boeing QB-47E Stratojet

QB-47E was the designation given to two B-47Es that were converted into prototype radio-controlled drones for use as targets or for other tasks deemed too hazardous to human occupants. Twelve more conversions were carried out by June of 1960.

The QB-47Es were equipped with control equipment, movie cameras, and other data collection equipment. They also carried ECM gear and chaff dispensers in order to make for a more realistic target during the tests. Just in case control of the drone was ever lost, explosives were carried so that the aircraft could be intentionally destroyed before it could wander into a populated area.

They were operated by the 3205th Drone Director Group at Eglin AFB between 1959 and 1960. Even though the QB-47Es were unmanned, they were generally considered as being too expensive to be treated as being expendable, and the guided missiles tested against them were usually programmed to make near-misses. Even in spite of such precautions, a QB-47E was inadvertently destroyed by a direct hit from a Bomarc missile.

Most of these drone aircraft were later destroyed during missile tests. Two survived to become JQB-47E for use in the testing of the Hughes AIM-47 long range air-to-air missile

Boeing WB-47E Stratojet

WB-47E was the designation assigned to converted B-47Es used for weather reconnaissance. They had nose-mounted cameras that recorded cloud formations, and they carried air-sampling and data recording equipment inside a sensor pod in the bomb bay in place of nuclear weapons. The defensive fire control system and the tail guns were removed.

The weather service received the first of 34 WB-47Es on March 20, 1963. They were modified by Lockheed-Marietta. They were operated by the 53rd and 55th Weather Reconnaissance Squadrons. The WB-47Es began to be replaced by WC-130 and WC-135 aircraft in 1965, but total phaseout took another 3 years. The last WB-47E--actually the last operational B-47 in the Air Force inventory--was delivered to Davis-Monthan AFB on October 31, 1969..jpg?width=1920&height=1080&fit=bounds)

Boeing RB-47E Stratojet

The RB-47E was a dedicated photographic reconnaissance version of the B-47E. It was initially known as the RB-47B, but it incorporated many of the features introduced on the E-model, and was soon redesignated as such.

A total of 240 examples were built by Boeing-Wichita. The first 52 examples were known as Model 450-216-29 by the company, with the remainder being known as Model 450-158-36.

As compared with the standard B-47E, the nose of the RB-47E was 34 inches longer so that it could house a special air-conditioned compartment for cameras and other sensitive equipment. Eleven cameras could be carried, along with ten photoflash bombs and supplementary photoflash cartridges for night photography. The bombing equipment was deleted, but the 20-mm tail armament and the A-5 fire-control system were retained. The crew was still three, but the bombardier now became the photographer/navigator. There was a return to the built-in JATO units that had been used on the B-47B. Although the RB-47E could be refuelled in flight, the fuel tankage was increased to 18,405 US gallons.

The first RB-47E flew for the first time on July 3, 1953. The last of 255 RB-47Es were delivered in August of 1955. The final 15 of the RB-47Es were completed as RB-47K weather reconnaissance aircraft.

Phaseout of the RB-47E began on October 14, 1957, when 51-5272 was retired to the boneyards at Davis Monthan AFB.

Boeing YB-47F Stratojet

From the inception of the B-47 program, it had been recognized that the development of efficient in-flight refuelling techniques would be absolutely essential for the full success of the relatively short-ranged Stratojet bomber. The first USAF in-flight refuelling tankers were converted B-29 and B-50 bombers, but by the mid-1950s the standard USAF tanker was the piston-engined Boeing KC-97. However, the use of the propeller-driven KC-97 as the tanker for the jet-powered B-47 had its drawbacks, since it could not climb to the B-47's best altitude, forcing the Stratojet to descend down to the tanker's level, wasting time and fuel. In addition, the KC-97 tanker was so slow that the B-47 tended to stall during the refuelling operation. In order to keep the B-47 from stalling, the slower KC-97 would often enter a shallow dive to pick up speed--a hair-raising operation for all concerned while the two planes were linked.

Clearly, aerial tankers with greater speeds would be required. In early 1953, two B-47Bs were allocated for tests with the British-developed probe-and-drogue aerial refuelling system. One was to be a tanker and the other a receiver. The converted aircraft were redesignated KB-47G and YB-47F respectively.

The YB-47F was a conversion of B-47B serial number 50-069. It was fitted with a probe in the nose for inflight refueling via the probe-and-drogue system. Unfortunately, the probe-and-drogue refuelling method did not prove to be effective for the B-47, and subsequent models were refuelled by the established flying-boom system. The speed problem was eventually solved by adding auxiliary jet engines to the piston-engined KB-50 and KC-97 tankers, which were used to provided additional bursts of speed during the refuelling operations.

Boeing RB-47H Stratojet

The RB-47H was an electronic reconnaissance and countermeasures version of the B-47E. It was built in response to a mid-1951 requirement laid down for an aircraft that would be capable of countering enemy air defense systems.

The nose carried an AN/APS-54 airborne radar detection system and APD-4 radar emissions receiver. An additional pressurized compartment was carried in the area formerly occupied by the short bomb bay. The compartment carried additional electronic equipment intended to locate and analyze enemy radar emissions as well as three operators, bringing the total crew to six. Self-protection equipment such as transmitters and chaff dispensers were provided for the jamming of enemy radar signals. The tail armament was retained.

The first RB-47H entered service with the 55th Strategic Reconnaissance Wing at Forbes AFB in Kansas in August of 1955. The last RB-47H was delivered in January of 1957. A total of 35 RB-47H aircraft were built, but three of these were delivered as ERB-47H electronic ferret aircraft.

The RB-47H carried out many ferret missions around the periphery of Soviet territory, and sometimes inside. On July 1, 1960, shortly after the U-2 incident, an RB-47H (53-4281) was shot down by Soviet fighters over the Barents Sea. Two of the crewmen ejected and were recovered, but the third was killed. The surviving crewmen were put on trial for espionage by the Soviets, but were eventually released on January 25, 1961.

In 1961, most RB-47Hs were upgraded to "Mod 44" or "Silverking" standards with more capable sensors. Among these was an ALD-4 receiver pod mounted inside a bulbous fairing on the lower rear fuselage, just beneath the forward edge of the rudder

The last SAC B-47, a RB-47H (53-4296) of the 58th Wing was flown to Davis Monthan AFB for storage on December 29, 1967, bringing the era of B-47 service with the USAF to an end.

Boeing ERB-47H Stratojet

ERB-47H was the designation assigned to three RB-47Hs (53-6245, 53-6246 and 53-6249) that were modified as special reconnaissance aircraft designed to detect and locate electromagnetic radio frequency emissions.

Like the RB-47H, the ERB-47H was equipped with a bomb bay pod that carried extra equipment and additional crew members, known as Electronic Warfare Officers (EWOs, aka Crows or Ravens). However, the normal crew complement of the ERB-47H was only five as opposed to six for the RB-47H, since the normal Raven One position in the RB-47H was eliminated and filled with additional equipment.

Like the RB-47H, the ERB-47H was sometimes sent on some rather dangerous missions near Communist airspace. An ERB-47H was intercepted and fired upon by a pair of North Korean MiG-17s over the Sea of Japan on April 27, 1965. Although heavily damaged, the plane managed to escape and make a safe landing at Yokota AB in Japan.

Boeing YB-47J Stratojet

The single YB-47J was a standard B-47E modified to carry and evaluate the new MA-2 radar bombing-navigation system that had been designed for the B-52.

Boeing RB-47K Stratojet

The last 15 RB-47E aircraft on order were completed as RB-47Ks. They differed from the RB-47E in being equipped for both weather and photographic reconnaissance missions at all altitudes. In addition to the standard set of cameras installed on the RB-47E, the K model high-resolution and side-looking radars for weather data gathering. In addition, air sampling equipment was provided that could be used to test the atmosphere for radioactive fallout. The first RB-47K was delivered in December of 1955.

The RB-47K was basically an airborne weather information gathering system They were operated by the 338th SRS, 55th Strategic Wing, and flew all over the world gathering weather data for SAC and sampling the radioactive fallout from foreign nuclear tests. They were phased out in the early 1960s.

Boeing EB-47L Stratojet

In 1963, 36 obsolescent B-47Es were modified as electronics communications aircraft under the designation EB-47L. The EB-47Ls were to serve as airborne relay stations between other aircraft (such as the USAF "Looking Glass" EC-135 command post or the Navy's EC-130Q) or between aircraft and ground stations during and after a nuclear attack.

Their serial numbers were: 52-031, 033, 034, 035, 038, 041, 059, 061, 066, 067, 069, 071, 078, 081, 082, 086, 099, 105, 154, 204, 211, 212, 214, 217, 220, 224, 291, 292, 298, 303, 305, 308, 309, 510, 513, and 53-2329

The EB-47Ls soon became obsolete and were phased out during 1965/66

CL-52 Flying Testbed For Orenda Turbojet

In spite of the large numbers of B-47s built, none of them ever ended up in the service of foreign air forces. There is, however, one significant exception--a B-47 loaned to the Royal Canadian Air Force as a flying testbed for the Orenda Iroquois turbojet.

In 1956, the USAF loaned B-47B serial number 51-2059 to the Royal Canadian Air Force for use as a flying test bed for the advanced 20,000 lb.s.t. Orenda Iroquois turbojet. A pair of Iroquois engines were to power the projected Avro CF-105 Arrow long-range interceptor, which was currently under development in Canada.

After delivery, the RCAF turned the plane over to Canadair Ltd to complete the required modifications. A separate pod for the test engine was installed on the starboard side of the rear fuselage underneath the horizontal tail. The pod was 30 feet long and about 6 feet in diameter The company assigned its own model number of CL-52 to the project. The CL-52/B-47B flew in RCAF markings, but retained the last three digits of its USAF serial number, which followed the prefix "X" to become the RCAF serial number.

The CL-52 spent a total of 31 hours in the air with the Iroquois engine. Most flights were routine, but on its only full-power flight the Iroquois engine suffered a fan blade failure which damaged the elevator and rudder of the CL-52. The aircraft, however, landed safely.

The first five Arrows (RCAF serials 25201 through 25205) were all powered by Pratt & Whitney J75 turbojets for the initial flight tests. The first Iroquois-powered Arrow was to be number 25206, which was being readied for its first flight when the entire Arrow/Iroquois project was cancelled by the Canadian government on February 20, 1959.

Following cancellation of the Arrow/Iroquois program, all Arrow airframes were ordered to be scrapped, including those in a partially-completed state on the production line. All that survives today is the front end of Arrow 25206 plus a couple of outer wing panels on display at the National Aviation Museum of Ottawa. A pair of Iroquois engines still survive, one in the National Aviation Museum and the other at the Canadian Warplane Heritage Museum in Hamilton, Ontario.

After the termination of the Arrow/Iroquois program, the Iroquois engine was removed from the CL-52 and the aircraft was returned to the USA in August of 1959. The plane was scrapped at Davis Monthan AFB shortly thereafter.

(Text by J. Baugher)

Post a reply

- Go to Previous topic

- Go to Next topic

- Go to Welcome

- Go to Introduce Yourself

- Go to General Discussion

- Go to Screenshots, Images and Videos

- Go to Off topic

- Go to Works in Progress

- Go to Skinning Tips / Tutorials

- Go to Skin Requests

- Go to IJAAF Library

- Go to Luftwaffe Library

- Go to RAF Library

- Go to USAAF / USN Library

- Go to Misc Library

- Go to The Ops Room

- Go to Made in Germany

- Go to Campaigns and Missions

- Go to Works in Progress

- Go to Juri's Air-Raid Shelter

- Go to Campaigns and Missions

- Go to Works in Progress

- Go to Skinpacks

- Go to External Projects Discussion

- Go to Books & Resources